A recent study published in Nature Communications Earth & Environment sheds light on an uncomfortable truth for the clean energy sector: even the world’s most advanced gigafactories produce huge volumes of internal emissions—and unless carefully controlled, they risk becoming external pollution and a loss of critical materials

The research, based on a leading lithium-ion battery plant in Germany, reveals substantial emissions of toxic and valuable substances into air, water, and soil. Despite operating under highly controlled conditions, the facility still produced staggering volumes of preventable waste.

Here’s what the study found—and why it matters for the future of battery production.

Where the Waste Escapes

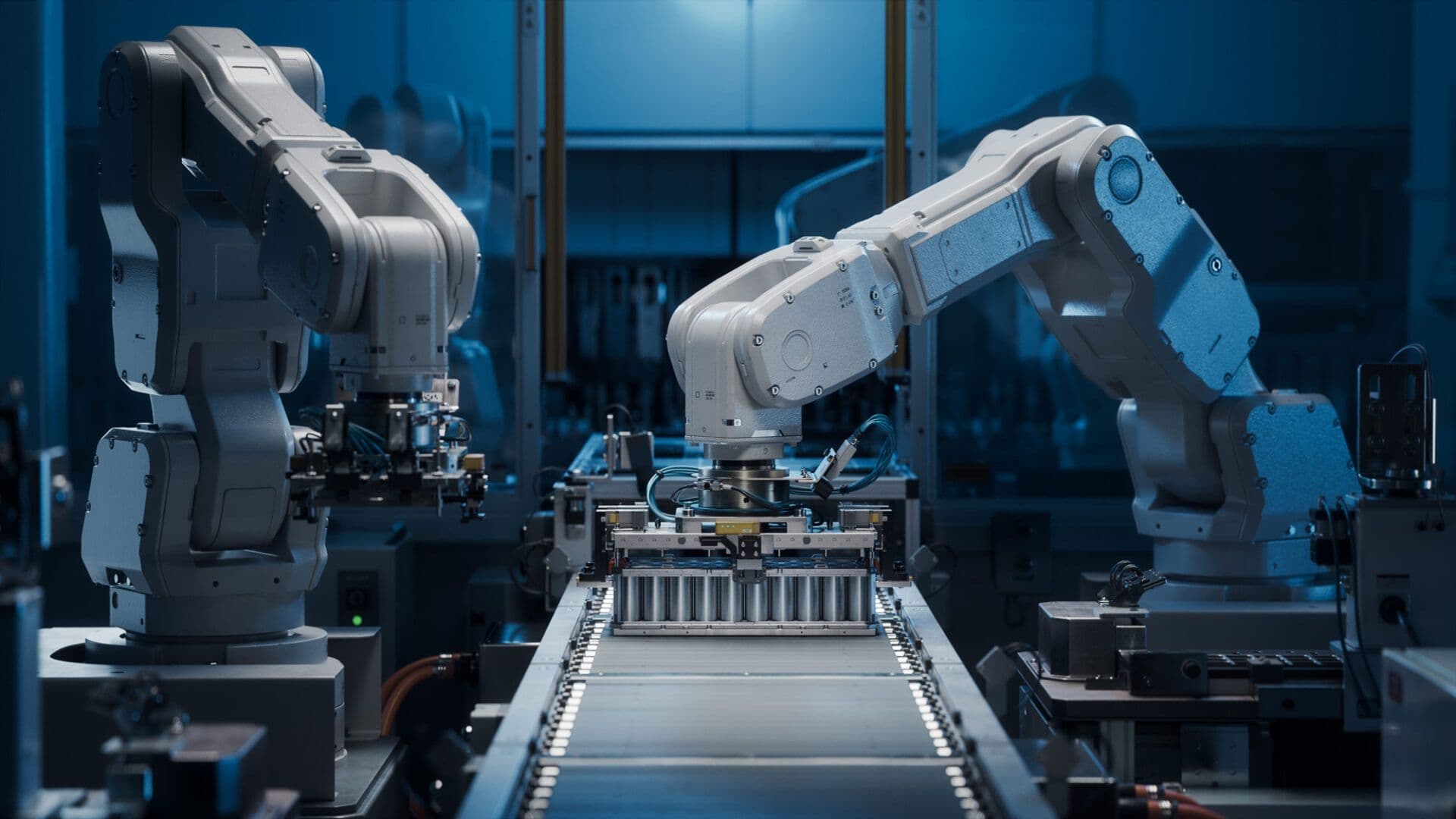

When we think of a gigafactory, we picture high-tech production lines, spotless dry rooms, and precision-engineered processes. But zooming in on the details tells a different story.

The study focused on the production of NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) battery cells, two of the most common chemistries in today’s market. Even in tightly sealed and automated environments, routine operations were found to generate significant emissions, including:

- Electrode coating and drying release solvent vapors such as NMP (from cathode lines) and large streams of water vapor (from anode lines)

- Cleaning and rinsing processes, which flush slurries of anode and cathode material, including critical metals into wastewater streams

- Powder handling and cutting, which emit fine dust from graphite, cathode powders, and collector foils

- Degassing and formation emit hydrocarbons and trace electrolyte by-products

- Ventilation systems, which struggle to capture ultrafine particles effectively

These processes may seem standard, but they collectively contribute to a major loss of materials and a growing environmental footprint.

Coated and Dried Anode Foil – Volkswagen

Breaking Down the Losses

So, what exactly is being lost?

The emissions identified include a combination of critical raw materials and hazardous chemicals, such as:

- Battery metals: lithium, nickel, cobalt, manganese, copper

- Graphite: a key anode material

- NMP (N-Methylpyrrolidone): a solvent with known health risks

- Hydrocarbons and other gases from cell formation (methane, ethylene, CO, CO₂)

- Acidic and alkaline cleaning agents

Many of these substances are not fully captured by existing filtration and exhaust systems. Instead, they end up scattered—into the air, into wastewater, or as sludge that’s difficult to treat or recover.

It's not just waste – it's a strategic loss.

Many of the materials emitted (lithium, cobalt, nickel, manganese, copper, and graphite) are classified as Critical Raw Materials under the European Critical Raw Materials Act (CRMA), with several labeled as Strategic Raw Materials due to their high economic importance and supply risk.

But these elements aren’t just essential for electric vehicles, they’re embedded in our everyday lives, powering smartphones, laptops, medical devices, and more. When they’re lost in production, it’s not only an environmental risk—it’s a missed opportunity to secure the resources our future depends on.

The Numbers Speak for Themselves

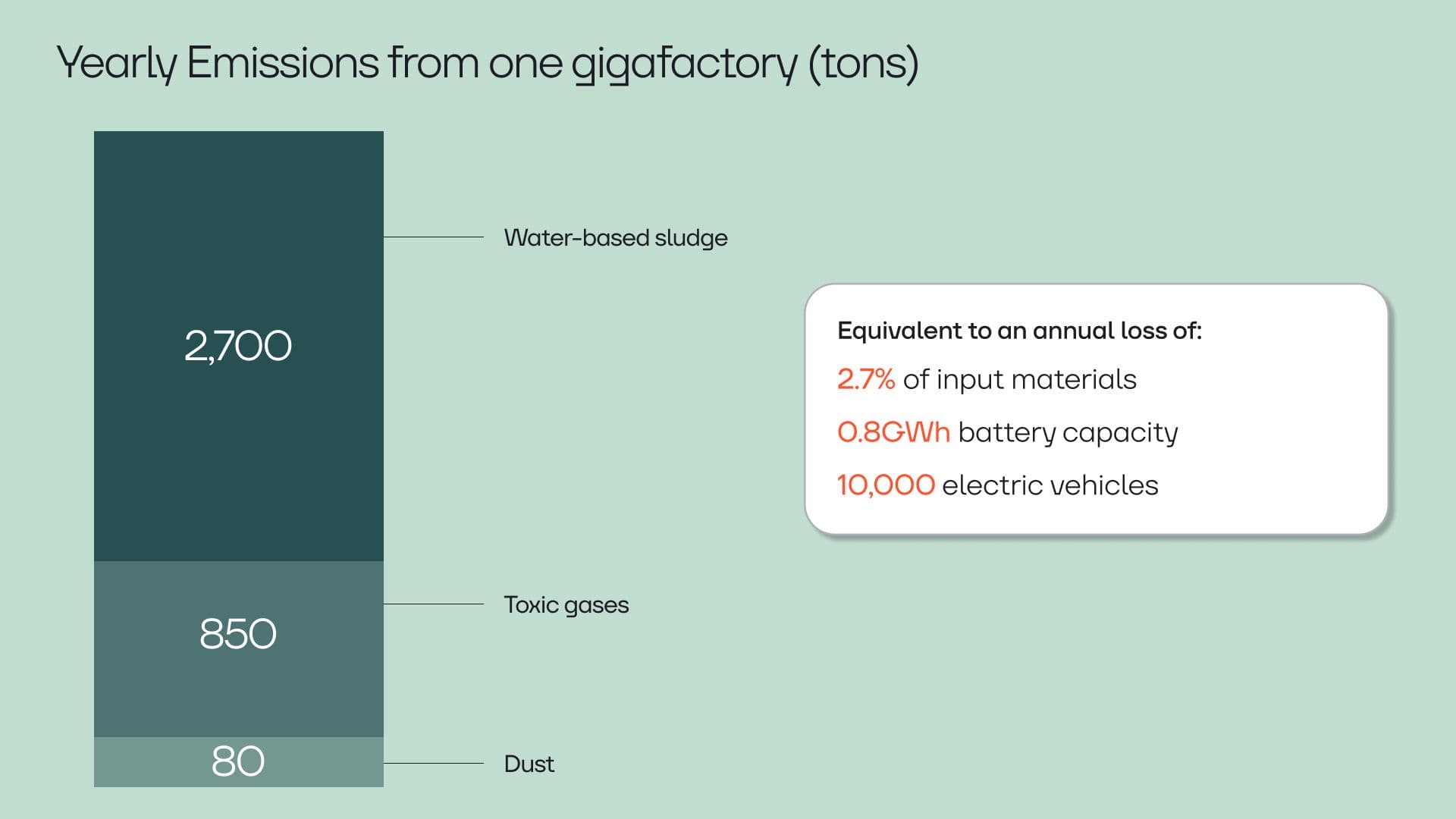

In just one year of full-capacity production, the studied gigafactory (32GWh) emitted:

- 2,700 tonnes of water-based sludge

- 510–850 tonnes of gases

- 80 tonnes of fine particulate dust

Altogether, this represents around 2.7% of all input materials lost in the process—a figure that’s hard to ignore in an industry defined by resource intensity.

Zooming in on cleaning processes alone, the study found that annual emissions from rinsing activities included:

- Up to 1,064 tonnes of NMC or 1,353 tonnes of LFP cathode slurry

- 563 tonnes of graphite

- 653 tonnes of NMP

That’s enough lost material to produce 0.8 GWh of battery capacity—powering over 10,000 electric vehicles—gone every year, from a single facility.

Why this Matters

Battery manufacturing is essential to the clean energy transition. But that doesn’t mean it’s inherently clean.

The emissions identified in this study carry serious implications:

- Worker health, from exposure to airborne solvents and ultrafine dust particles

- Product quality, as contamination risks rise within controlled environments

- Environmental integrity, through persistent waste and pollution if not captured

- Economic efficiency, with valuable materials literally going down the drain

In short: it’s a systemic loss of safety, sustainability, and profitability.

Good News: We Can Do Better

The study doesn’t just reveal a problem. It offers a roadmap for meaningful improvement. The researchers recommend targeted interventions:

- Advanced filtration systems, capable of capturing fine and ultrafine particles in dry rooms

- Solvent recovery technologies, especially for NMP

- Wastewater treatment systems, designed for material separation and recovery

- Circular design principles, embedded from the start—not added later as compliance measures

These are not futuristic solutions, they’re available now. But they require a shift in mindset: from compliance to opportunity. From clean looking to clean functioning.

Circularity Starts at the Source

The battery factories of tomorrow need more than precision robotics and spotless floors. They need intelligent systems that prevent valuable materials from slipping away—and that protect people, processes, and the planet in the process.

At DREV, that’s exactly what we’re building.

We’re redefining what “clean” means in cleanroom environments. Our technology captures airborne dust, chemical vapors, and rinse waste before they become problems. And we help partners recover value, economically and environmentally, from what others see as loss.

Because true state-of-the-art production doesn’t stop at output. It starts at the source.