“Safety first” is something we’ve all heard before – whether it was your parents reminding you to buckle your seatbelt, wear a helmet, or tie your shoelaces properly. In everyday life, these small precautions help us avoid accidents we can see coming.

But what about the risks we can’t see?

In advanced manufacturing, especially battery production, safety is about more than just being cautious around heavy machinery. It’s also about the air we breathe. Microscopic particles, invisible to the naked eye, float through the workplace, potentially affecting both workers and the very products they’re making.

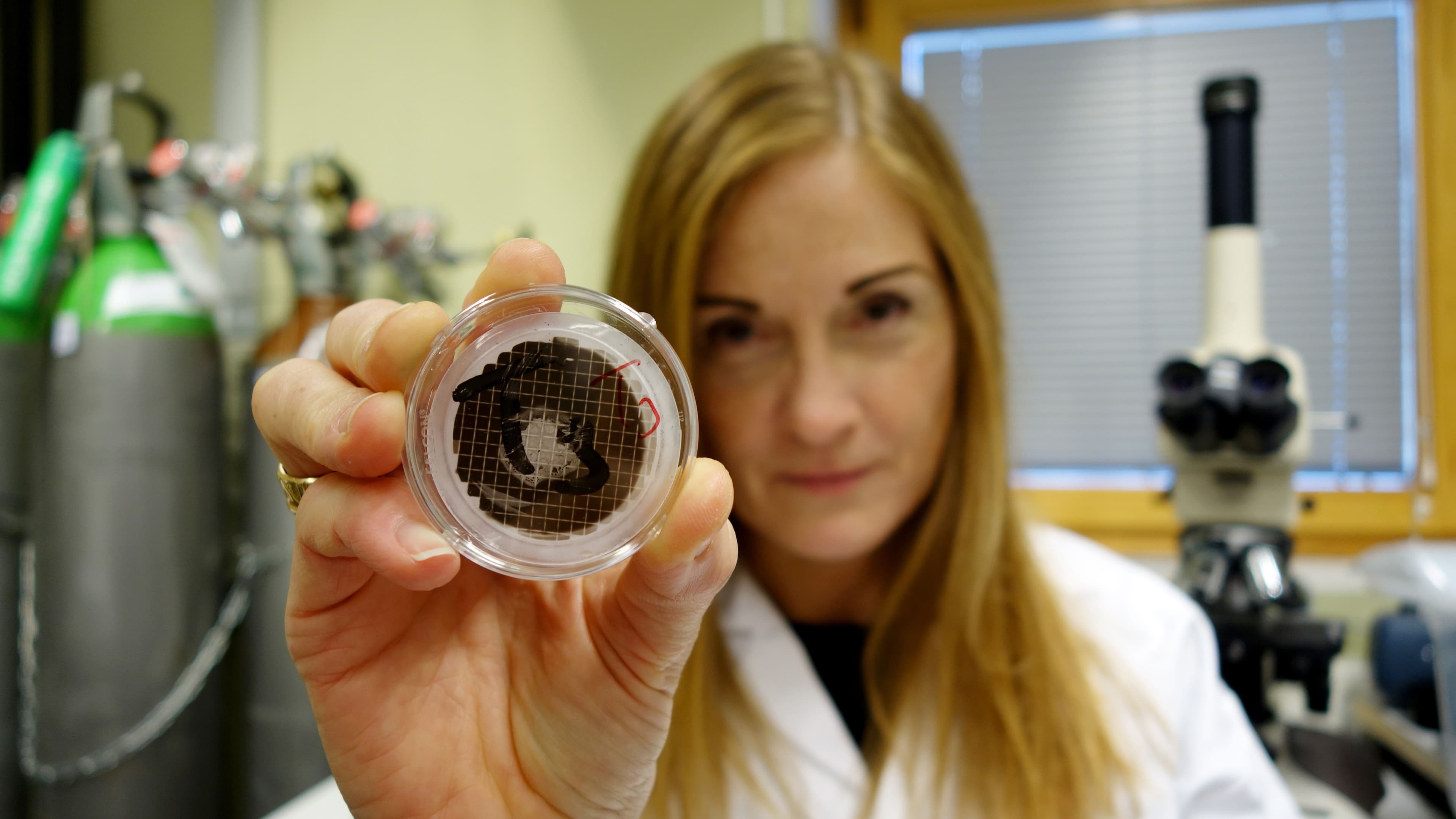

To understand how airborne particles impact battery manufacturing, and what can be done to keep workers safe, we sat down with our scientific advisor, Dr. Christina Isaxon, a leading expert in aerosol technology and workplace exposure. Christina has spent years studying how tiny airborne particles behave, how they interact with the human body, and how industries can minimize health risks.

Aerosols, Particles & Workplace Safety

What do you study? And what exactly are aerosols?

I study airborne particles, known as aerosols, how they are generated, how they behave, and their impact on human health. While aerosols include both particles and gases, my research focuses on the solid and liquid particles suspended in air, which are the most challenging to measure and often pose health risks.

Aerosols are a major contributor to both indoor and outdoor air pollution, and are generated from many different sources, such as industrial processes or transportation emissions. My research involves real-world assessments, which includes measuring emissions and exposure risks in workplaces, homes, and outdoor settings, alongside controlled lab studies. In partnership with medical researchers, we also perform cell studies to better understand how particles and cells interact.

One of the areas I focus on is workplace aerosols, particularly those that contain metals or engineered nanoparticles, which are particles that have been intentionally produced for a certain purpose rather than occur naturally.

Sometimes, the levels of exposure to these particles can be high or uncertain, but even small amounts may pose health risks. By enhancing our methods for characterizing, measuring, and identifying these particles, exposure risks can potentially be lowered, improving safety in the workplace.

What happens when humans are exposed to aerosols, and why is particle size so important for health risks?

Whether an airborne particle poses a risk depends on two key factors: how long the person has been exposed and how harmful the particle itself is. In other words, it’s about concentration, time, and toxicity.

Some particles are inhaled and exhaled without any harm, while others, particularly those that can reach deep into our lungs, can settle in our respiratory system. The size of the particle plays a crucial role as it determines how far into the lungs it can reach and how likely it is to stay there.

For example, larger particles tend to get caught in our nose and throat and are easier to expel. On the other hand, smaller particles, especially nanoparticles, can penetrate deep into our lungs, where our body’s natural removal systems aren’t as effective. This makes smaller particles potentially more dangerous than larger ones – not just because they can travel deeper, but because they can stay in our bodies longer and directly interact with our cells and tissues. Whether a particle dissolves in our body also plays a role in its health effects, as insoluble particles are more likely to remain in our bodies and potentially cause long-term inflammation.

Adobe Stock

Are nanoparticles harder to detect? What challenges exist in measuring them?

Yes. One of the biggest challenges we face is that no single instrument can accurately measure the full size range of airborne particles simultaneously. Traditional air monitoring tools typically focus on either mass concentration, which reflects larger particles due to their greater mass, or particle number concentration, which is better at detecting smaller particles like nanoparticles.

Nanoparticles are particularly tricky to work with as they have a tendency to aggregate, or clump together, forming larger clusters. This makes them harder to detect for instruments designed only to detect small particles, as they might completely miss the larger aggregated forms. Mass-based methods like collecting dust on filters may also overlook the nanoparticles due to their low individual mass.

To get a full picture, multiple measurement methods are needed – including real-time particle counters, size-selective sampling, and chemical analysis. But even then, there are gaps, which is one of the reasons why workplace exposure assessments can be so challenging.

What are the safety measures to protect humans from contaminants?

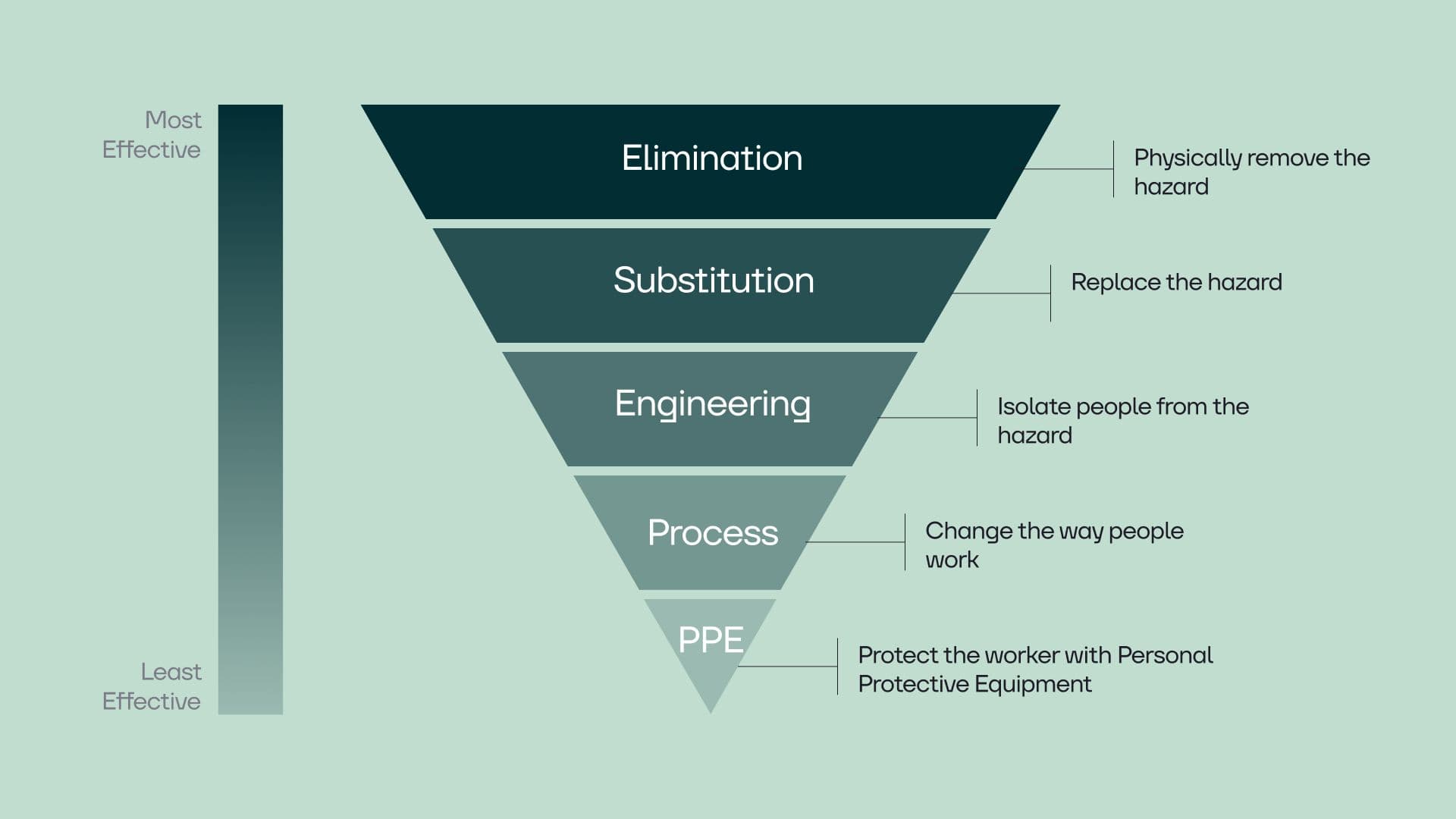

The NIOSH Hierarchy of Controls is a widely used framework for protecting workers from airborne contaminants, which ranks safety measures from most to least effective:

- Elimination – The most effective approach is to completely remove the hazardous substance from the process.

- Substitution – If elimination isn’t possible, replacing the hazardous material with a safer alternative is the next best option.

- Engineering Controls – When a hazardous substance must be used, the focus should be on containing it. This can include automation, enclosed workspaces, ventilation systems, or fume hoods to prevent exposure.

- Process and Administrative Controls – Changing work procedures, limiting exposure time, and implementing training programs can help reduce risks.

- Personal Protective Equipment (PPE) – The last resort is using protective gear like respirators, masks, gowns, and gloves, reducing direct exposure.

While PPE plays an important role in protection, it is the least effective measure because it relies on individuals using it properly rather than removing the hazard itself. PPE works best when combined with engineering controls and exposure monitoring to minimize risks at the source.

Hierarchy of Controls

Contamination Control in the Battery Industry

What sparked your interest in DREV, and how does your research relate to the battery industry?

I first connected with Thomas Tingelöf, DREV’s CTO, when we discussed the challenges of contamination control in battery production. His perspective on the industry’s needs was fascinating, and our discussions were incredibly engaging – it felt like solving a puzzle together. I found myself saying, “Don’t think about it that way, think about it like this,” and realizing that my expertise could genuinely contribute to their work.

Workplace-generated aerosols are a major focus of my research, which are often made up of materials that can pose serious health risks, like metals. Many risks are well-documented, such as welding fumes, which release harmful metals that can lead to both respiratory and systematic diseases. However, there are still many unknows, especially when it comes to engineered nanoparticles used in advanced manufacturing, where we don’t fully understand the long-term health impacts yet. This knowledge gap highlights the urgent need to measure emissions, study exposure risks, and ensure proper safety measures.

With my background in aerosol measurement and exposure assessment, I saw a clear opportunity to contribute. Understanding how airborne particles behave, how they spread, and how they impact both workers and production processes is essential for creating safer, cleaner manufacturing environments. DREV’s work aligns perfectly with this mission, and that’s what drew me in.

DREV Team & Christina Isaxon

Cleanrooms are used in battery manufacturing to minimize contamination. Are these environments also designed with worker safety in mind?

In industrial settings, cleanrooms are primarily created to safeguard products and processes from contaminants, rather than protect humans. The contaminants that are controlled in cleanrooms are generated from the workers activities, such as their movements, which clothes they wear, and even breathing. Processes like material handling and assembly can also release fine metal particles into the air, potentially exposing those who are close to the source. To enhance worker safety, measures like localized extraction systems and personal monitoring help reduce exposure to fine and nanosized particles.

Battery technology is rapidly advancing. What risks do new technologies like solid-state batteries and silicon anodes introduce during manufacturing?

As battery technology, or any technology for that matter, continues to evolve, new risks emerge. For example, when manufacturing batteries with silicon anodes, silicon dust particles are produced. These particles are small enough to penetrate deep into our lungs when inhaled, potentially causing irritation. When these particles are at the nanoscale, they could reach further and interact at a cellular level, sparking concerns about the long-term health impact.

On the other hand, solid-state batteries use solid electrolytes instead of liquids, which reduces the chemical risks such as flammable substances. However, the solid materials may bring other hazards, especially if they contain nanostructured components. These nanoparticle related risks are particularly relevant during activities like handling powders, mixing, and processing materials, where the particles can be released into the work environment. Similarly, recycling processes such as crushing release particles into the air, putting workers at risk of inhalation.

As these technologies move into large-scale production, exposure monitoring, updated safety protocols, and ensuring proper containment will be essential to ensure worker safety.

Cleanroom in Battery Manufacturing – Verkor

Your research into WEEE recycling uncovered several risks from airborne contaminants. What specific risks do battery metals pose during these processes?

In WEEE (Waste Electrical and Electronic Equipment) recycling, processes like shredding, grinding, and dismantling release airborne metal particles. These require careful handling to minimize the risk of long-term exposure. Our research found significant amounts of copper, zinc, aluminum, and lead in these emissions, which pose health risks to workers and can potentially contaminate the surrounding outdoor environments.

Similarly, the battery industry works with materials that demand special handling due to their reactivity and potential health impacts. During both manufacturing and recycling, nickel, cobalt, and lithium can become airborne, leading to occupational exposure and the possibility of environmental contamination.

Some battery metals require extra attention, especially when airborne.

For instance, prolonged exposure to cobalt has been linked to lung conditions, while nickel is known to cause allergic reactions. Lithium, due to its reactivity, requires careful handling when in powder form to avoid irritation.

Over time, some of these metals can accumulate in our bodies, leading to serious health issues. How they affect us depends on their chemical form and how our bodies respond. Some metals dissolve easily in bodily fluids, increasing the likelihood of entering our bloodstream and harming organs. Given the handling of these small particles in battery manufacturing, it’s important to monitor them closely, contain them properly, and ensure that there are effective filtration systems in place to keep workers safe and protect the environment.

Battery Recycling – Ascend Elements

Regulations & Future Airborne Safety

How are regulations regarding particle exposure and toxicity established?

Workplace exposure limits are mainly determined by toxicology studies, often using animal models to determine the dose at which harmful effects begin. Scientists then apply safety factors to estimate an exposure level that’s considered acceptable for humans.

However, these limits aren’t purely scientific; they also factor in economic and political factors. Setting stricter regulations can be costly for industries, so sometimes the exposure limits are set on what’s feasible for the business to achieve rather than what’s safest for humans. This means that the occupational exposure limits allow for a certain percentage of workers to get sick from the exposure in question. Also, when new advanced materials are introduced into production, regulations fall behind.

Many workplace exposure limits focus on short-term safety, but less is known about the long-term effects of chronic exposure. What risks might we be overlooking?

Yes, this is an area where more research is needed. Most of the exposure limits we have today are based on studies that focus on short-term toxicity. This means that we might not fully understand the long-term effects of low-level, chronic exposure, especially when it comes to newer substances like engineered nanomaterials. Understanding the long-term effects of fine metal particles, particularly nanoparticles, is still an evolving area of research. Ensuring that regulations keep pace with new findings will be key to long-term worker safety.

Adobe Stock

Do you think current safety regulations are strong enough to protect workers? If not, what would you change?

Honestly, no. Current exposure limits are based on studies that were conducted before we fully understood how nanoparticles behave, and they rarely account for the effects of long-term exposure. Nanoparticles interact with our bodies in ways that are different for larger particles, yet many regulations still focus on mass-based limits instead of considering particle number or surface area, which are more relevant for evaluating their impact.

Regulations often take years to update, while industries are constantly innovating and introducing new materials. This creates a gap where there may be health risks before safety standards are revised.

If I could change one thing, it would be to set exposure limits based solely on toxicology, without any economic or political compromises. Workplace safety should always reflect the latest scientific findings, ensuring that workers are protected as technology progresses. Regulations need to evolve with research, especially as technology advances and new materials become more prevalent. Work should be stimulating and rewarding, not a cause for sickness.

If you could share one or two things that you think the public should know about aerosols, what would they be?

- Just because you can’t see a risk doesn’t mean it’s not there. By nature, humans associate danger with what they can see, like heavy machinery, but some of the most harmful hazards are microscopic.

- Scientific research and technology move fast, and regulations often take time to catch up. Industries develop new materials and processes faster than policymakers can assess their risks, meaning that workplace safety standards do not fully protect workers. Companies must take initiative to go above and beyond what’s legally required and implement preventative measures, not just compliance.

Adobe Stock