DREV for Battery Manufacturers

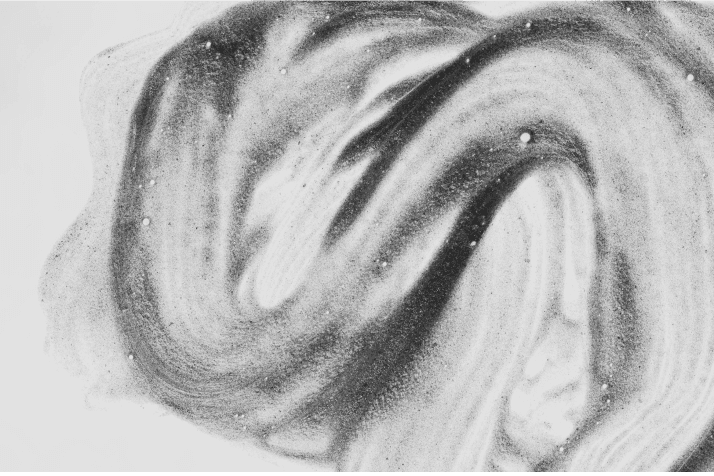

Black dust in dry rooms drives yield loss, cleaning shutdowns, and operator exposure — especially as footprints scale. DREV integrates advanced technologies and safety measures to ensure a cleaner, safer, and more sustainable manufacturing process.

Protect dry room conditions

Our dry brush technology eliminates the need for water and solvents – keeping the dew point stable during and after decontamination.

Reduce employee exposure

Our sealed capture systems reduce airborne particle exposure, mitigating workplace risks.

Recover value from dust

Vault helps you to recover valuable material and repurpose it, working directly with recovery partners for reintegration rather than being lost to filters or waste streams.

DREV for Battery Recycling

Fine black dust escapes easily across zones, creating cross-contamination risk and lost recovery yield. DREV's innovative solutions maximize material recovery and maintain high standards of cleanliness, helping facilities meet regulatory requirements while promoting sustainable practices.

Increase recovery yield

Vault safely captures and segregates fine material that typically vanishes to waste streams.

Prevent cross-contamination

Our Vault solutions keep black mass from migrating into clean zones, protecting process stability and enhancing recycling efficiency.

Meet tightening regulations

Supports safer handling of hazardous particles and cleaner operation, aligned with upcoming regulations.

DREV for Mining & Refining

Hazardous fine particles pose fire, exposure, and environmental release risks in high-throughput operations. DREV optimizes mining and refining by improving material recovery and safety standards, protecting the environment and ensuring safer operations.

Recover fine fractions

Capture valuable metal dust that spreads through ventilation and manual cleanup.

Reduce emissions

Control hazardous particulates at the source to minimize release into surrounding areas.

A new standard for safety

Dry capture and sealed handling reduce both worker exposure and dust-related thermal events.

Learn more about DREV

About us

We’re on a mission to revolutionize how industrial spaces maintain cleanliness and efficiency. Learn more

Our team

We bring years of experience from places like Panasonic Energy of North America and PowerCell. Learn more about us.

Insights

Read our blog to get the latest thoughts from our team. DREV insights

Want to know more?

Schedule Consultation

Battery Elements

These are the elements DREV aims to collect.

3

6.491

Li

Lithium

6

12.011

C

Carbon

11

22.99

Na

Sodium

13

26.981

Al

Aluminium

14

28.085

Si

Silicon

14

30.973

P

Phosphorus

16

32.06

S

Sulfur

20

10.078

Ca

Calcium

22

47.867

Ti

Titanium

24

112.414

Cr

Chromium

25

59.93

Mn

Manganese

26

55.845

Fe

Iron

27

58.933

Co

Cobalt

28

58.693

Ni

Nickel

29

63.465

Cu

Copper

30

65.38

Zn

Zinc

35

79.904

Br

Bromine

46

106.42

Pd

Palladium

48

112.414

Cd

Cadmium

82

207.2

Pb

Lead

One technology. Multiple applications

Vault

StationaryConstant, controlled particle collection at all levels of battery manufacturing. Learn more

Vault

AutonomousReduce the need for human intervention in restricted and highly contaminated areas. Learn more